*Competitive Quality* - HAN HSIN PRECISION INDUSTRIAL Builds Business Connection to Car & System Manufacturers

by Tanya Shih, Fastener World

The heartland of metal fabrication is in Asia and Taiwan is one of those countries that developed its metal fabrication industry at early time with quite mature technology. The sophistication and customizability of Taiwanese products also draw the attention of many purchasers in the market. Since the inception in 1996, Han Hsin Precision Industrial Co., Ltd. has been the designated supplier of CNC machining & processing industries. Its case nuts, copper nuts with plastic inserts, electric hand-wrenching screws, various mechanical and axle parts are applicable to electronics, machines, automobiles/motorbikes, medical, telecommunication industries.

Defending Quality and Enhancing Efficacy to Satisfy the Company, Employees and Customers

Han Hsin is able to supply various metals like copper, aluminum, stainless steel, Ti-alloy, and heat resistant alloy as well as the following optional anodizing, heat treating, electroplating, stamping, and assembly service, helping customers control and maintain smooth communication in every process, shipment, and quality.

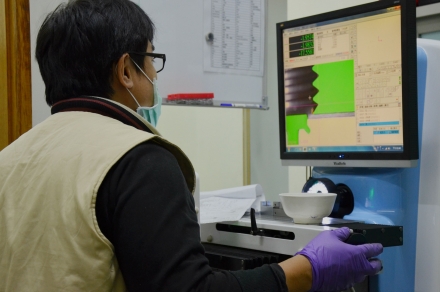

As a saying goes, “To do a good job, one must sharpen his tool first.” Han Hsin’s factory is installed with over 100 sets of computer control and CNC lathes and its QC division has several quality testing devices like thickness testers, hardness testers, surface roughness testers, and image profiling machines demonstrating the manufacturing ability of the company. With the stable operation, Han Hsin released good news again in 2016. Its new factory built 2 years ago has finished the pre-manufacturing test and has been installed with Japanese sliding head CNC lathes and related inspection machines which will greatly improve the quality and capacity. It is able to process wires in 3mm-51mm diameter and the precision can be kept within 0.005mm, fully satisfying or exceeding customers’ requirements for high precision.

General manager Han Long Chang said, “Better technology continues to appear, and therefore the arts of manufacturing must also be improved. Han Hsin adopts the manufacturing facilities and machine tools which are the most state-of-the-art in the market to greatly boost production efficiency, alleviate employees’ pressure, reduce energy consumption & manufacturing cost, and achieve more stable quality and capacity. We believe Han Hsin’s biggest business advantage comes from our spontaneous action that reduces customers’ purchasing cost, elevates ours and customers’ competitiveness in the market, and fully satisfies the company, employees, and customers.”

Green Manufacturing to Keep Pace with Global Leading Suppliers

Han Hsin seeking sustainability and green manufacturing is well-known in the industry for its “competitive quality. Its factory has been certified by ISO 9001 and ISO 14001. All manufacturing procedures in its factory are compliant with RoHS regulations. It hopes to contribute its own effort to advocate the idea of “Love the Earth”. It is now applying for TS 16949 and will focus more on precision components supplies to car and system manufacturers.

Subscribe