Jun-En’s Gratex Belts and Compound Balanced Belts Surprise Fastener Companies

The ISO9001 certified Jun-En Enterprise Corporation, which has introduced the SAP system into its company, is one of the leading metal mesh products and related processing machines manufacturers in the world. Its customers mainly come from Taiwan, Asia, America, EU, the Middle East and Australia. With abundant experience and the strong R&D ability, Jun-En has supplied high quality products and service to its global customers for more than 30 years and continues to satisfy every customer’s demand for customized products. Its metal mesh products include balanced belts, rod reinforced belts, flat wire belts, wire ring belts, ladder belts, high temperature belts, chain driven belts, curve conveyor belts, spiral conveyor belts, plywood veneer dryer belts, gratex belts, double balanced belts, compound balanced belts, one direction belts and other special types, mainly made of 314, 310S, 304, 316 high quality stainless steel. Gratex belts and compound balanced belts are particularly developed for the heat treatment application of fasteners and have gained very positive feedback from heat treating plants in the Middle East, Taiwan and Southeast Asia, where many Taiwanese companies have set up their own heat treating plants. Its products also take a leading market share in relevant Taiwanese industries that use metal mesh belts.

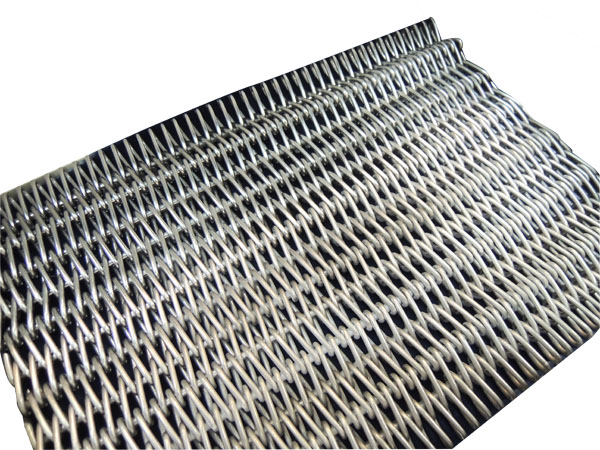

Gratex Belt- Left-round and right-round spirals are alternately arranged and jointed with straight rods. Its advantages are: (1)Surface is flat and unstable items can be carried; (2)The allowable belt tension is capable for heavy load; (3)Belt can be used at high temperature; (4)Having fine mesh, the belt can be used for transportation of small items.

Compound Balanced Belt- The left-round and right-round spirals are tightly together alternately and jointed with straight rods. Its advantages are: (1)Since the surface is flat and smooth, the belt can carry small items and unstable products; (2)The allowable tension is high, so that heavy loads can be transported; (3)The belt strength against pressure is high, so that the belts can be used for processing under pressure; (4)The belt can be used at high temperature.

Jun-En said, “Our metal mesh belts are all produced by our self-developed high-speed precision machines. We not only have a complete range of product series in stock, but also conduct quality control that is 100% compliant with int’l standards to meet customers’ strict requirements for lead times and customization. In addition, as screws are usually heat treated at the temperature of 800-900, metal mesh belts manufactured by Jun-En, which can sustain the temperature of up to 1,050°C, demonstrate better even heat distribution on metal mesh belts and more durable feature. Considering the future market demand, Jun-En will also focus more on the R&D of new materials/products, making the service life of metal mesh belts longer, improving product quality and enhancing the ability to offer customers all-in-one service. We expect to become the best partner for your demand for metal mesh belts.”

Jun-En contact: Ms. Enping Yang Email: enping.yang@junen.com.tw

Subscribe