T. Kato - The World’s First “Wood Shrinkage Tracking” & Anti-vibration Washer

by Dean Tseng, Fastener World

T. Kato started off as an R&D department of Kato Hardware. In 1988 it was established as a company manufacturing self-developed construction materials like “T-Balance” table adjusters and “Relevel” foundation washers. One of its featured products is “TIGHTNIK”, a first-of-its-kind anti-vibration washer used in over 15,000 Japanese buildings every year.

“Magic Ring” + “Disc Springs”

Ultimate Solution to Loosening Due to Wood Shrinkage

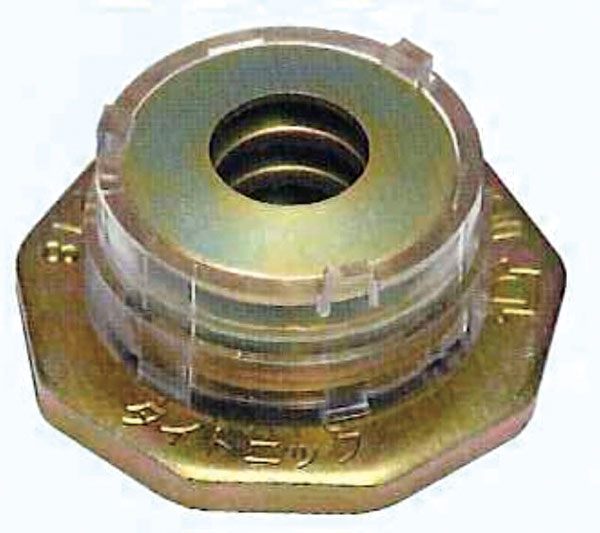

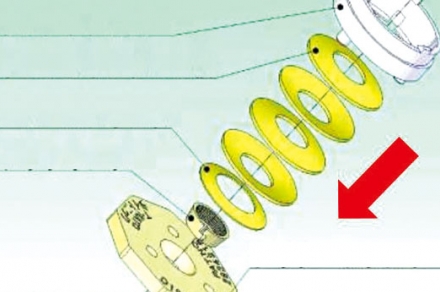

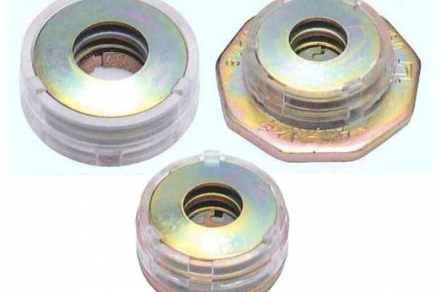

In timber framing, the connecting portion of woods are reinforced by hardware. However, wood and metals have different properties and therefore “wood shrinkage” driven by seasonal changes causes bolts to loosen. This had been an unsolvable problem until President Toshiyuki Kato came up with an idea to use unconventional hardware on wood fastening, which led to the creation of TIGHTNIK. It consists of a plastic cover, 4 disc springs, a tamper-proof spring, a magic spring and an outer washer. The springs are designed to track and adapt to wood shrinkage. As the wood shrinks, the springs push the tapering “magic ring” towards the outer washer. During this process, the magic ring decreases its diameter and keeps gripping the bolt. Working like a wedge, the magic ring prevents the outer washer from returning and thus maintains tightening of the wood. This innovative structure enables the magic ring to fasten the bolt tightly.

The Stronger the Vibration, the Tighter It Fastens

Distinctly different from average washers that adopt coil springs, TIGHNIK uses disc washers which have a larger spring constant than that of coil springs, and thus it can minimize the appearance of gaps. When an earthquake strikes, the disc springs turn all the force of vibration into one that pushes the magic ring to the outer washer and prevents it from returning. This mechanism ensures TIGHNIK’s vibration resistance does not deteriorate in the face of a force as huge as an earthquake.

The president added, “We use the term ‘disc springs’ to refer to washers that are tapered into a shape of disc. They have a distinctive advantage over coil springs because they can bear substantial loads within a very small space. TIGHNIK has a compact height of only 4mm to 6mm with the ability to track wood shrinkage, but a coil spring washer would need two to three times the height to harness the function of tracking.” Furthermore, TIGHNIK, suited for exterior wall fastening, is treated with galvanized electroplating on its metal portion for anti-corrosion, and its resin portion is made of polycarbonate for impact resistance.

Aimed for Diverse Application

TIGHTNIK is the world’s first anti-vibration washer patented in the U.S., China, Hong Kong, Taiwan, and South Korea. It has passed axial force tests and NAS 3350 vibration tests. “We supply it domestically to the fastening of warehouse palate racks, wooden playground facility, solar panel racks, roads and bridges. Its application will be limitless when we apply weather-resistance heat treatment to it,” said the president, “We have the creativity and R&D capabilities to revolutionize the niche market. We will aim at broadening the use of TIGHTNIK beyond the building industry.”

T. Kato’s contact: President Toshiyuki Kato

E-mail: tanino@t-kato.co.jp

Subscribe