Second to None: Construction Screw Leader Bi-Mirth Corp.

Bi-Mirth Corporation, one of the pioneers of the fastener industry in Taiwan, was founded in 1985 and located at Gangshan District, Kaohsiung City. In our previous interview with Bi-Mirth, we discovered that the company purchased another 3-in-1 manufacturing machine from Germany, and integrated SIDASA equipment from Spain in its coating facility in order to increase efficiency and decrease human error during production. Other than brand new machinery, there has been continuous research and development for better products. Recently, Bi-Mirth has developed a new type of heat treatment and surface treatment style for fasteners that can withstand extreme temperatures and climates with the absence of hydrogen embrittlement and fractures. We’re here once again with insider scoop for the latest developments within the company from President Thomas Shih and General Manager Tom Shih.

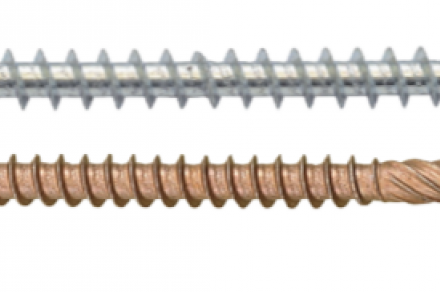

New Design: QuickDrill V

One of the most recognized products in the European market is the QuickDrill series developed by Bi-Mirth Corporation. The fifth generation of the series has been developed after countless designs, suggestions from customers, and internal testing. This model focuses on providing swift and clean drills. This is accomplished by thinning the thread, which also reduces drilling torque without drastically affecting torsional strength. The toils of R&D have finally paid off and the standards have been raised as the company announces the release of the QuickDrill V this year.

New & Patented Technology: Extreme Temperature Resistance

In addition to new product designs, Thomas Shih, the president, has proudly presented his newest certification from SGS for his patented technology that combines heat treatment and surface treatment alterations in order to combat cold embrittlement up to -60 Celsius. The test setting for the screws was in a chamber with controlled temperature and humidity. Bi-Mirth devotes part of its efforts on developing fasteners that stay resilient during drastic temperature change due to global warming and its extreme side effects.

New Markets: Japan, New Zealand, and Australia

When asked about the focal market for Bi-Mirth this year, Tom Shih, the general manager stated that the prime markets the company wants to develop are based at Japan, New Zealand and Australia as there have been adjustments to construction and safety regulations in these countries within the past few years. Australia, in particular, has had construction accidents, which alerted the government and resulted in legislative changes.

Future Directions

According to Thomas, “Bi-Mirth is one of the few manufacturers that cover most of the production process, which includes forming, electroplating, coating, and packaging. The company strives to compete in the industry with updated equipment and a heavy focus on quality and development. The aim for Bi-Mirth is to increase product yield rate from 70% to 80 – 90% in the future and to accomplish what others cannot.”

Bi-Mirth Contact: General Manager, Tom Shih

E-mail: tom@bimirth.com.tw

Subscribe