Leading and Professional Clips Approved by Global Automotive OEM Hsiung Jen Industrial Co., Ltd.

by Dean Tseng, Fastener World

Hsiung Jen was established in 1982 with the headquarter and factory located in Chiayi.

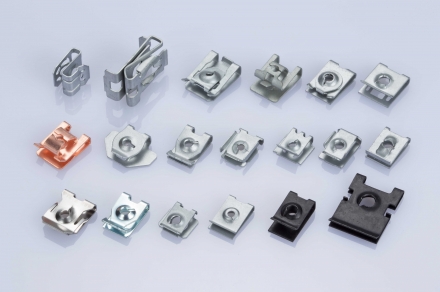

Today, the company aims to become the most professional clip manufacturer using carbon steel, stainless steel, conductive metal, and other materials to form, process and produce products. It is already a qualified Tier 1 parts supplier and supplies to the major automotive and motorcycle OEM worldwide.

Hsiung Jen’s clients span across north America, Europe and Asia where the automotive industry is flourishing. 75% of its revenues is from export and the remaining 25% comes from the supply to the domestic OEM. It currently has bases in Fujian Province of China and Shanghai City, and has strategic partners scattering across Europe, Asia, Australia and other countries.

One-Stop Production Line & German Auto Inventory System

One of the biggest features of Hsiung Jen is its one-stop production line, through which the company covers the whole manufacturing process by itself, ranging from tooling design & build, metal stamping & forming, heat treatment, and coating. Its manufacturing plant has 1,600 pieces of tools available for production at any time. The company has 35 sets of multi-axis forming machines to stabilize the manufacturing process at a high Ppk value of above 1.67 and push the daily capacity to 3 million pieces. It can provide clips to automotive, domestic appliances, electronics, multi-functional products, and sports equipment industries.

Hsiung Jen is also particular about improving product management and efficiency, so it introduced Hanel LEAN-LIFT automatic inventory system from Germany that helps save more than 60% of storage space through vertical storage management. “The basic requisite for inventory management is optimized inventory, accurate delivery and consistent quality. Our principles to industrial development is to build a factory environment that is adaptive, resource-efficient and ergonomic,” said the company.

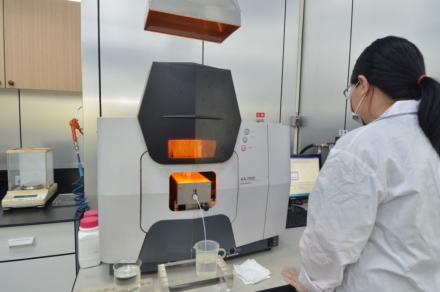

Compliant to International High-end Automotive Production Quality

Hsiung Jen implements quality management in product R&D through mass production. It is IATF16949, ISO9001, ISO14001 certificated, and has become a qualified supplier to GM, Nissan, Proton, HONDA, and Jiangling Motors. It also produces components for many car brands such as Ford, Volvo, BMW, Audi, Toyota, Mitsubishi, and Yamaha. High-end quality compliance enables the company to meet low-volume, high-variety and 0ppm demands from the automotive supply chain.

Looking ahead, Hsiung Jen thinks stable revenue growth and profit is the approach that every company takes to maintain competitiveness. “In the mid-term, we will increase our export proportion, complete the construction of our 3rd manufacturing plant, and add more strategic partners to provide the drive for our growth. In the long run, we will target our goal at helping client with their product design and setting our foot in developing ‘intelligent manufacturing equipment’ !” The Taiwan headquarters, the 3rd manufacturing plant and new business unit, and the sales routes of the branch in China will together bring a whole new breakthrough to Hsiung Jen’s global supply chain!

Hsiung Jen’s contact: Duke Chen

E-mail:ad02@hsiungjen.com

Subscribe