Bi-Mirth to Steal the Fastener Show in Las Vegas- Limit-breaking Hexfast & Timberfast Screws

As an adventurer with a keen perception of market, Bi-Mirth has been pouring investments and resources into the improvement of corporate strengths. It will announce at International Fastener Expo 2019 the rollout of hardwood screws, U.S.- standard Hexfast and Timberfast screws as well as the latest self-drilling screw series. For the European market, the all-new QuickDrill V series is launched, and it is in the process of getting ETA. Each product line comes with higher performance and endurance.

New Bi-Mirth Construction Fasteners

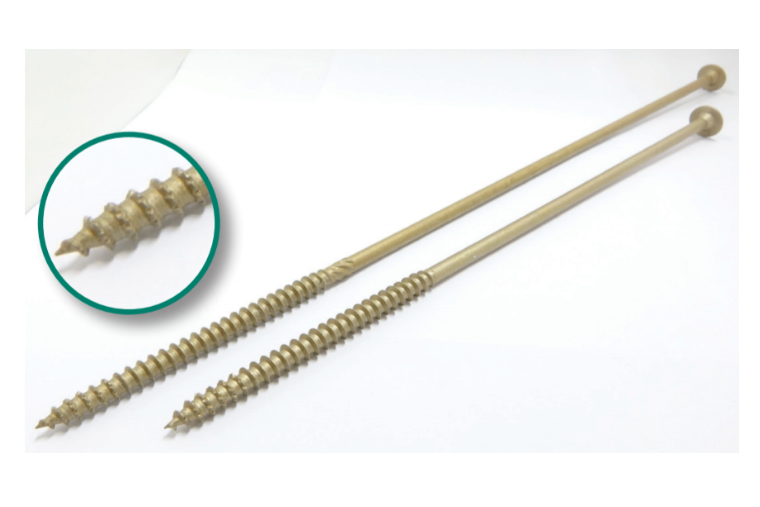

The market for prefabricated buildings in the U.S. and the EU inspired sales manager, Tom Shih, to develop a series of products for these buildings. Many American and European prefabricated construction companies are rolling out buildings because they are cheaper than customized buildings, and the building materials are more environmentally friendly. One of the topics about prefabricated house is hardwood LVL timber. There is a demand for these hardwood LVL beam in these prefabricated houses. Bi-Mirth developed a new hardwood LVL screw with lower drilling torque and less prone to cracking. The new screw is called BM HD, and it will be launched in the Fastener Fair Las Vegas.

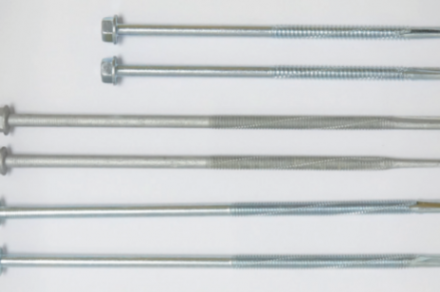

Targeting the American market, Bi-Mirth has rolled out the American-standard and patented HexFast Screws and TimberFast Screws. Both the screws have a special thread design that offers lower drilling torque and strong pullout. These screws are ICC-approved which guarantee that they are code compliant. Bi-Mirth will be adding new ranges to HexFast and TimberFast in the ICC soon.

As to the self-drilling series, Bi-Mirth introduced self-drilling screws numbered 6, 8 and 10 this year with faster drilling time, better corrosion resistance (1000~6000 SST hours, under ASTM B116 & 16~60 cycles, under DIN 50016), and less risk of hydrogen embrittlement (can withstand temperature down to -30 degree C [-22 degree F]). These self-drilling screws can go through steel plates as thick as 20 mm (0.8 in.).

Newly-Designed QuickDrill Series

Besides the American-standard screws above, Bi-Mirth is constantly making breakthroughs in European Standard screws. It wasn’t long after the rollout of QuickDrill III that Bi-Mirth immediately introduced the refined version of the edition. The latest refined QuickDrill V offers smoother driving, lower drilling torque, and minor impact on timber. The patented “crystal thread” will increase the size of the minor diameter to create spaces for wood particles to move while not affecting the pullout and lowers the drilling torque.

Go Big or Go Home. Be on the Top of the World!

Bi-Mirth spends an annual investment of USD 2~3 million on equipment purchased from the U.S. and Europe. Its plant is equipped with six fully automatic screw forming machines from Germany. The company spends another USD 100,000 ~ 150,000 every year on independent research and development to keep its quality, technique, and manufacturing capability level with the American and European competitors. This corporate belief has made Bi-Mirth irreplaceable in the global wood screw market. Bi-Mirth has its own inspection lab which offers various inspection items for customers’ specific demand.

This year Bi-Mirth purchased two high speed heading forming machines from South Korea to boost manufacturing capacity. “Using advanced equipment allows us to save labor costs. We used to have a guy looking after three machines, but now we just need one for each person with the same high output. Better equipment brings higher capacity and most importantly, it continues to bring better quality. This year, a new SIDASA Coating Line is up and running in the electroplating line for the black sealer in order to effectively reduce recess fill and increase the output capacity.

Bi-Mirth's Contact: Bi-Mirth Sales Department

General E-mail:sales@bimirth.com.tw

Subscribe