News

October Feature: Hisener / CTSP

Add to my favorite

2025-10-21

Chinese fastener exhibitors at international trade shows have surged dramatically. Hisener has become a trusted fastener partner for global buyers by leveraging strong production capacity, excellent quality control, and highly competitive pricing strategies. CTSP deepens its presence in Europe's high-end market and emerging Asia Pacific markets, supplying global clients with cost-effective threaded inserts and clinching fastener solutions. CTSP strengthens long-term client partnerships, maintains leadership in the global high-end sector, and demonstrates robust international competitiveness and growth potential.

Hisener Leads Globalized Chinese Fasteners: Dominance in Capacity, Quality, Price

In recent years, the number of Chinese fastener exhibitors at international trade shows has surged dramatically, highlighting the rapid global expansion of Chinese fasteners. Riding this wave, Hisener has become a trusted fastener partner for global buyers by leveraging strong production capacity, excellent quality control, and highly competitive pricing strategies.

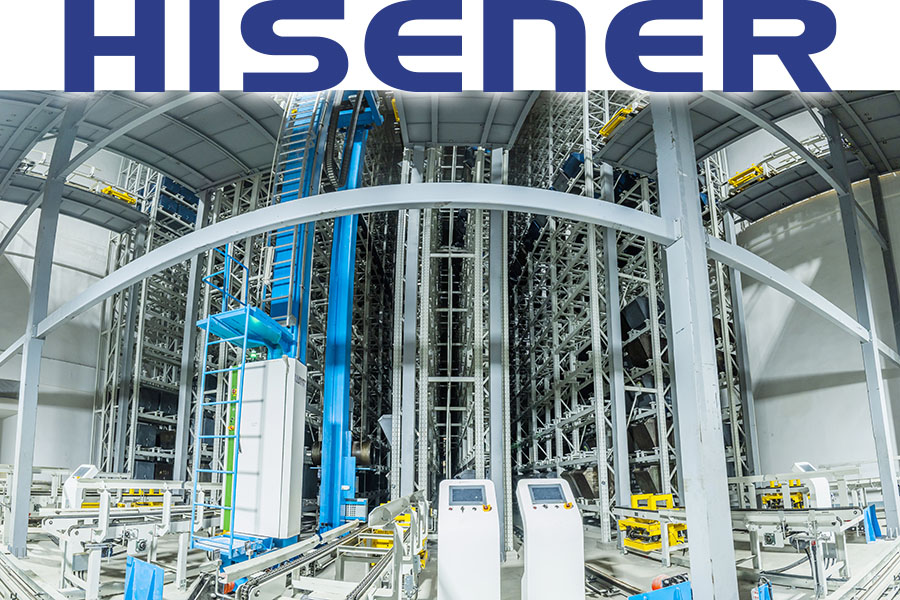

Strong Production Capacity to Meet Diverse Global Demands

Hisener has continuously expanded its production capacity in recent years. The automated smart factory launched in 2022 has significantly improved production efficiency. In early 2025, a new stainless steel product plant was built, equipped with 50 sets of high-efficiency equipment, achieving a monthly output of 300 tons. The total stainless steel monthly capacity has exceeded 500 tons, bi-metal screws maintain a monthly output of 150 tons, and carbon steel products remain stable at 1,500 tons, forming a complete and flexible production system.

This highly efficient and large-scale production setup allows the company to quickly respond to different market and customer needs, providing stable and timely supply assurance. The advanced data monitoring and production process optimization of the smart factory ensure consistent product quality and stable performance with every batch. One of Hisener’s core competitive strengths lies in its strict quality control. The company uses 304, 316, and 410 types of stainless steel materials. Its products cover screws, threaded rods, bolts, nuts, washers, anchor bolts, pins, and fasteners for solar photovoltaic panels, meeting the needs of multiple industries.

Its stainless steel deck screws have obtained the EU CE certification, and its stainless steel wood screws have earned the ETA 22/0584 construction certification. The company is equipped with salt spray and acid rain corrosion resistance testing equipment to conduct uninterrupted 24-hour corrosion resistance tests on every product batch, ensuring excellent performance in harsh environments. The bi-metal screws successfully developed in 2023 combine the properties of stainless steel and alloy steel, showing a maximum penetration force of 12.5 millimeters and strong pull-out resistance. They offer outstanding performance and excellent cost-effectiveness and are widely used in construction, solar energy, and machine manufacturing.

Excellent Cost-Performance to Maximize Value

Utilizing mature processing technology and smart production, the company has successfully lowered production costs while maintaining highly competitive prices without sacrificing quality. General Manager Simon Liang said, "Creating maximum value for clients with high cost-performance during economic downturns is key to our continuous growth and expansion in the global market. Whether in the best or the worst times, Chinese fasteners and Hisener have become indispensable partners in the global industrial chain." Hisener not only solidifies its position in the Chinese market but also effectively penetrates Europe, America, and emerging countries, becoming an essential procurement choice for global buyers.

Adhering to ESG Principles to Build a Foundation for Sustainable Development

Hisener actively practices ESG by integrating sustainable management concepts throughout its corporate governance and production processes. It focuses not only on environmentally friendly product performance but also emphasizes fulfilling social responsibilities, aiming to create long-term value for clients and partners through green manufacturing and good governance. In today’s complex and ever-changing global economic environment, it upholds the belief that "whenever there is demand, the Hisener team will be there." With a passion for quality and flexible market responsiveness, Hisener has laid the foundation for the Chinese fastener industry to advance globally, opening a bright future for the international expansion of Chinese manufacturing.

Hisener's contact: Simon Liang, General Manager

Email: simon@hisener.com

CTSP Smart Green Manufacturing Deepens Roots in Europe & Emerging Markets

As the global manufacturing industry shifts toward high quality and low pollution, Chin Tai Sing Precision Manufactory (CTSP) leverages its technical strength and diverse supply capabilities to deepen its presence in Europe’s high-end market and emerging Asia Pacific markets, showcasing strong overseas competitiveness. The company supplies global clients with cost-effective threaded inserts and clinching fastener solutions.

Leading a New Blue Ocean of Sustainable Development

CTSP integrates IoT equipment on production lines with AI and machine learning to precisely monitor production data. It has developed a smart demand forecasting system and a process self-optimization mechanism while enforcing strict batch number management. These initiatives enhance traceability, production efficiency, and quality stability.

Environmentally, CTSP holds RoHS certification and actively promotes low-carbon manufacturing. It carries out carbon inventories and provides carbon footprint reports with CBAM data, helping clients meet international environmental and carbon reduction standards. Energy optimization and waste management further drive CTSP’s green smart manufacturing goals.

Meeting Diverse High-End Industry Demands

CTSP develops high-precision products with tolerance accuracy of ±0.01 mm to meet stringent performance and reliability needs from clients in Europe, America, and Japan. It has entered supply chains in automotive, aerospace, electronics, telecommunications, construction, and defense sectors. Equipped with automated machinery and experienced teams, the company achieves a monthly output over 20 million pieces and near-zero PPM ultra-high yield rates. Besides brass, it offers customized stainless steel, aluminum, and other material designs, responding flexibly to varied market demands and becoming a trusted partner for global high-end industries.

Expanding Global Sales Footprint

CTSP serves clients in 50 countries, with 80% from Europe and America and 20% from Asia. Its European focus targets advanced economies like Germany, France, and the UK, where strict environmental regulations and green technology standards present strong business opportunities. CTSP collaborates with leading automotive and aerospace manufacturers in Europe, capitalizing on its green energy and high-performance parts expertise. Rapid urbanization and infrastructure growth in Asia-Pacific and other emerging markets fuel demand in automotive, electronics, and machinery sectors. Strategic markets also include India and Japan. Leveraging geographic and supply chain advantages, CTSP meets local demands and steadily grows market share.

High Cost-Performance Ratio Driving Customer Growth and Value Enhancement

Focusing on cost-effectiveness and competitive pricing, CTSP provides global clients with high-performance products at affordable prices. Automated production lowers manufacturing costs, while R&D innovations optimize materials and processes to ensure quality and price balance. This cost-performance strategy extends product applicability and supports one-stop customized design, production, and inspection services. CTSP strengthens long-term client partnerships, maintains leadership in the global high-end sector, and demonstrates robust international competitiveness and growth potential.

CTSP's contact: General Manager Lee

Email: inquiry@ctsp-insert.com.tw

海迅

中國緊固件

智慧工廠

不鏽鋼

碳鋼

複合螺絲

金泰興精密

綠色製造

歐洲市場

螺紋埋入件

壓鉚扣件

物聯網

AI

低碳

CE

ETA

ESG

Hisener

Chinese fastener

smart factory

stainless steel

carbon steel

bi-metal screw

CBAM

CTSP

Chin Tai Sing Precision Manufactory

green manufacturing

European market

threaded inserts

clinching fastener

IoT

low carbon

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

緊固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

2026美國鳳凰城螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

德國杜塞道夫線材展

Fastener

Hand Tool

Hardware

Component

Fastener World

Wire Dusseldorf

Fastener Fair India

Fastener Fair Vietnam

Fastener Fair Mexico

Fastener Poland

Fastener Fair Italy

IFE

Fastener Fair Global

Chicago Build

READ NEXT

2025-10-21

Subscribe