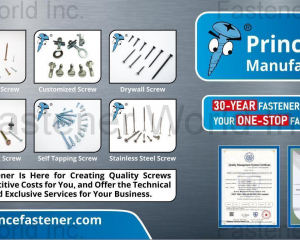

PRINCE FASTENER (NANTONG) MANUFACTURING CO., LTD.

About Company

PRINCE FASTENER (NANTONG) MANUFACTURING CO., LTD.

CHINA

Room No. 223, No.980, Qinghewan Road, Qingpu District, Shanghai, China

+86 13611808580 , +86-18930191254

+86 18930927024

Please login

Model / Specification

Prince Fastener Chipboard Screw

Country of Origin

CHINA

Surface Treatment

Prince Fastener Chipboard Screw

Material

Prince Fastener Chipboard Screw

Alias

Prince Fastener Chipboard Screw

Patent

Prince Fastener Chipboard Screw

Head Marking

Capacity

Prince Fastener Chipboard Screw

Minimum Order Quantity

Prince Fastener Chipboard Screw

Detailed Description

What is the Best Screws for Chipboard?

Prince Fastener Chipchipboard screws are self-tapping screws most ordinarily designed with one thread that runs all the method from the bottom of the top to the tip.

The thread of a prince fastener chipboard screw is usually deemed as ‘coarse’. this implies there’s a biggerdistance between the peaks of the thread. Therefore, the screw can undergo the soft material plenty faster.

Chipchipboard screws are available 2 common types: sleek shank and full thread.

A2 chipboard screw

(A2 chipboard Screw – full thread)

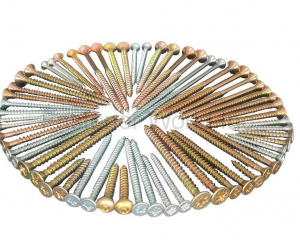

Chipchipboard screw sorts and sizes

Like any facet of construction, choosing the suitable material is critical for guaranteeing the project is completed to its highest potential. It’s continually vital to shop for a prince fastener prime qualityof chipboard screw because the heads of inferior screws will become broken throughout modification.

Prince fastener Chipboard screw product features

Although there are many types of Chipboard Screw, they all have the following main characteristics:

(1) Are generally made of carburized carbon steel (accounting for 99% of the total product). It can also be made of stainless

steel or nonferrous metals

(2) The product must go through heat treatment; carbon steel Chipboard Screw must go through carburizing treatment, stainless steel Chipboard Screw must go through reliable solution hardening treatment, and make the Chipboard Screw meet the standard requirements of mechanical properties and performance.

(3) The product has a high surface hardness and good core toughness. That is, “soft inside and hard outside” is the Prince fastener Chipboard screw to meet the requirements of performance

(4) The surface of the product needs surface protection treatment, generally electroplating treatment. Some products require phosphate treatment (phosphating) on the surface, such as wallboard Screw for phosphating.

(5) Adopting a cold heading process for production. It is recommended to use a high-speed mean heading machine, high-speed wire rolling machine, or high-speed planetary wire rolling machine to ensure product quality. Such production of Chipboard nail head molding, thread quality is high.

Prince Fastener Chipchipboard screws are self-tapping screws most ordinarily designed with one thread that runs all the method from the bottom of the top to the tip.

The thread of a prince fastener chipboard screw is usually deemed as ‘coarse’. this implies there’s a biggerdistance between the peaks of the thread. Therefore, the screw can undergo the soft material plenty faster.

Chipchipboard screws are available 2 common types: sleek shank and full thread.

A2 chipboard screw

(A2 chipboard Screw – full thread)

Chipchipboard screw sorts and sizes

Like any facet of construction, choosing the suitable material is critical for guaranteeing the project is completed to its highest potential. It’s continually vital to shop for a prince fastener prime qualityof chipboard screw because the heads of inferior screws will become broken throughout modification.

Prince fastener Chipboard screw product features

Although there are many types of Chipboard Screw, they all have the following main characteristics:

(1) Are generally made of carburized carbon steel (accounting for 99% of the total product). It can also be made of stainless

steel or nonferrous metals

(2) The product must go through heat treatment; carbon steel Chipboard Screw must go through carburizing treatment, stainless steel Chipboard Screw must go through reliable solution hardening treatment, and make the Chipboard Screw meet the standard requirements of mechanical properties and performance.

(3) The product has a high surface hardness and good core toughness. That is, “soft inside and hard outside” is the Prince fastener Chipboard screw to meet the requirements of performance

(4) The surface of the product needs surface protection treatment, generally electroplating treatment. Some products require phosphate treatment (phosphating) on the surface, such as wallboard Screw for phosphating.

(5) Adopting a cold heading process for production. It is recommended to use a high-speed mean heading machine, high-speed wire rolling machine, or high-speed planetary wire rolling machine to ensure product quality. Such production of Chipboard nail head molding, thread quality is high.

Message Board