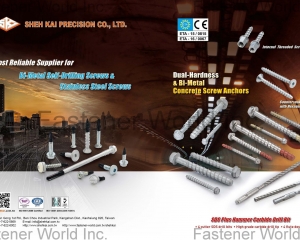

SHEH KAI PRECISION CO., LTD.

About Company

SHEH KAI PRECISION CO., LTD.

TAIWAN

No. 1, Beng Gong 1st Rd., Ben Chou Industrial Park, Kangshan Dist., Kaohsiung 82059, Taiwan

886-7-6225669

886-7-6226002

Please login

Model / Specification

Dual Hardness Heat-Treatment

Country of Origin

TAIWAN

Surface Treatment

Dual Hardness Heat-Treatment

Material

Dual Hardness Heat-Treatment

Alias

Dual Hardness Heat-Treatment

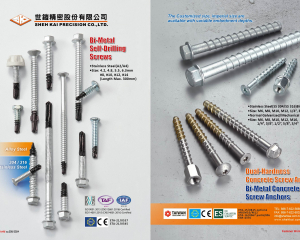

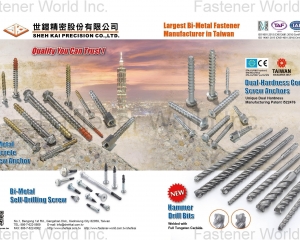

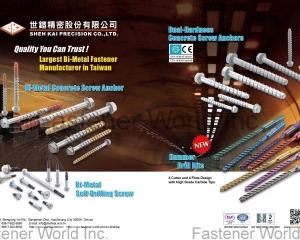

Bi-metal Concrete Screw Anchors

Patent

Dual Hardness Heat-Treatment

Head Marking

Capacity

Dual Hardness Heat-Treatment

Minimum Order Quantity

Dual Hardness Heat-Treatment

Detailed Description

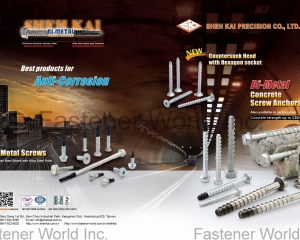

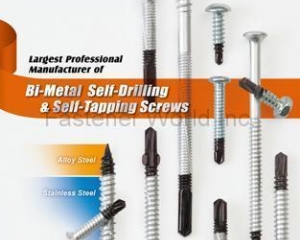

Sheh kai Precision uses a two step heating technique where a carburized technique is used first to harden the outer

layer of the screw, and then an induction heat treatment used only for the drilling/tapping portion of the fastener.

Separate processes and separation of the techniques as well as the area allows Sheh Kai to manufacture a fastener

with the desired hardness for drilling / tapping the required materials while also leave the desired amount of ductility

to the load bearing area of the fastener. This would safeguard the fastener itself from the effects of hydrogen and

corrosion induced embrittlement, preventing delayed and unexpected failure, thus enhancing the performance of

the fastener.

Two Steps Heat - Treatment

1st step – Case hardening to provide the shank of the screw with adequate

strength,good ductility, and hydrogen embrittlement resistant characteristics.

2nd step –Selective through hardening to provide the drill point and lead

threads with good drilling and tapping performance.

layer of the screw, and then an induction heat treatment used only for the drilling/tapping portion of the fastener.

Separate processes and separation of the techniques as well as the area allows Sheh Kai to manufacture a fastener

with the desired hardness for drilling / tapping the required materials while also leave the desired amount of ductility

to the load bearing area of the fastener. This would safeguard the fastener itself from the effects of hydrogen and

corrosion induced embrittlement, preventing delayed and unexpected failure, thus enhancing the performance of

the fastener.

Two Steps Heat - Treatment

1st step – Case hardening to provide the shank of the screw with adequate

strength,good ductility, and hydrogen embrittlement resistant characteristics.

2nd step –Selective through hardening to provide the drill point and lead

threads with good drilling and tapping performance.

Message Board